The Victorian basket is 7.5" in diameter and can be made as deep as you like by adding more basket rings. The pattern calls for the rings to be 1/4" thick but use thicker wood for a deeper basket.

The hot air balloon scene has four layers. It will be a fairly easy pattern to cut. A 24" X 24" pice if 1/4" thick plywood is more than you need to cut the pattern so it won't be too expensive to cut.

Over at the Bob's Home Woodshop YouTube channel, Bob always does a nice job explaining his scroll saw techniques. In this video, he cuts my Mother's Day pattern. It is about 13 minutes long.

YouTube is a good place to learn techniques but it can also be a bad place to learn questionable techniques. When you find a guy like Bob, who has been scrolling for years you can feel confident he is not getting off the tracks. That does not mean you must follow any of our videos as gospel. One technique will work well for one person and the next person will find that same technique challenging or too expensive. Attaching patterns to the wood is one example. I use spray adhesive but many scrollers hate spray adhesive. If you are new to scrolling then check out Bob's video on the nine techniques of getting the pattern onto the wood.

Like any craft/art you need to be exposed to many techniques and then pick and choose. Eventually, you will have your own personalized methods.

Link to this pattern

Special Offer from Seyco. Save $50 to $75 depending on the model you purchase.

Use the codes below to get a large discount on the Seyco Scroll Saws.

There are only a few days left until this offer expires. These are significant price reductions. If you are looking for a great scroll saw, take advantage before the offer expires.

Visit Seyco for more details.

$12 per sheet of 12 coins plus $3.50 shipping

Inlay with a 1" Forstner Bit.

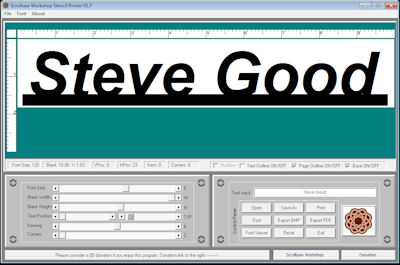

The perfect way to sign your work.

Hot Air Balloon Pattern

Email Newsletter Readers: Remember that the Newsletter is just a copy of the daily blog post. To see the post in its proper formatting click this link. If you ever misplace a pattern or any item you see here you can always find it on the blog. Everything stays on the blog forever.

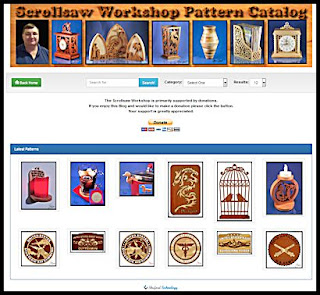

Every Scrollsaw Workshop Pattern from 2007-2023 on USB drive, or Instant Download. Over 4,300 Patterns!

Purchase the entire Scrollsaw Workshop pattern catalog for offline access.You will never run out of fun patterns to cut.

Two delivery options.

After payment, you will receive an email with the download link. This is a large file. You should not attempt to download it on a tablet or smartphone. It is a compressed file that will need to be extracted to your hard drive. Basic computer skills are necessary to extract the file.

Click this link to order the USB Drive

The USB drive contains all the Scrollsaw Workshop Patterns. The drive is $25 plus shipping and handling. Now with the new distributor the drive ships to the US and many other countries. The shipping can get expensive to some international locations so the Instant download option above is probably more desirable.

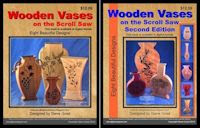

My two "Wooden Vases on the Scroll Saw" books make it easy.

The books are $12 each and available for instant download after purchase. Click for Video Demonstration.

My Sponsors:

Support the businesses that support our community.

Home of Pegas scroll saw blades.